VX pipe clamps

- Brass

- Internal thread, external thread and connection pieces (straight, angular, T-shape 90°)

- Especially for plastic pipes (HD-PE and ND-PE) from ½” (external diameter 20 mm) to 3″ (external diameter 90 mm)

VX applications Fast, safe, versatile!

- In industry, in the open, in greenhouses, in domestic water systems. Quite simply anywhere PE piping systems need be installed, be it below or above ground, or for fixed or mobile installations

- For drinking water, industrial water and many other liquid media (also highly viscous fluids), and for *gas

VX pressure and temperature resistance

- Operating pressure max. 16 bar

- *Gas max. 4 bar and only in conjunction with VX pipe gas sleeve for the stabilisation of the PE pipe

- Operating temperature from -20°C to + 120°C

VX characteristics and properties

- High quality standard

- Perfect installation made simple

- Resistant to heat, cold, pressure and corrosion

- Optimal free-flow cross section

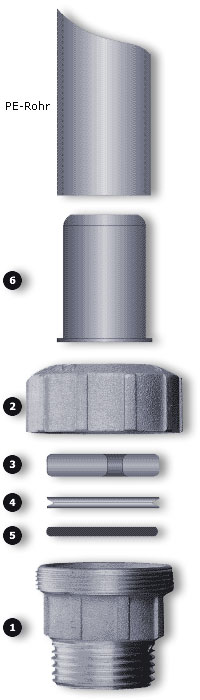

- The patented VX pipe clamping ring (3) in conjunction with the other components of the seal guarantee that the pipe fits tightly and offers absolutely reliable protection from any self-loosening of the PE pipe, even if the PE pipe has not quite been cut to a right angle of 90°

VX installation instructions

- Put VX nut (2) (from size 2 1/2” VX flange) over PE pipe. Followed in sequence by VX pipe clamping ring (3), VX pressure ring (4) and VX O-ring (5).(For medium gas: simply insert VX pipe gas sleeve (6) into the PE pipe as far as it will go)

- Insert PE pipe with all above-mentioned seal components into the housing (1) of the VX pipe clamp connection and make sure that the PE pipe is in contact with the base area (bar).

- Tighten VX nut (2) (or flange). You’re done!